UILA.

UILA is not only radically changing how we commute from A to B, but also provides a direct answer to fighting climate change.

At the same time, it delivers a feature set of digital functions and assets that are far beyond the standard in today’s bike industry.

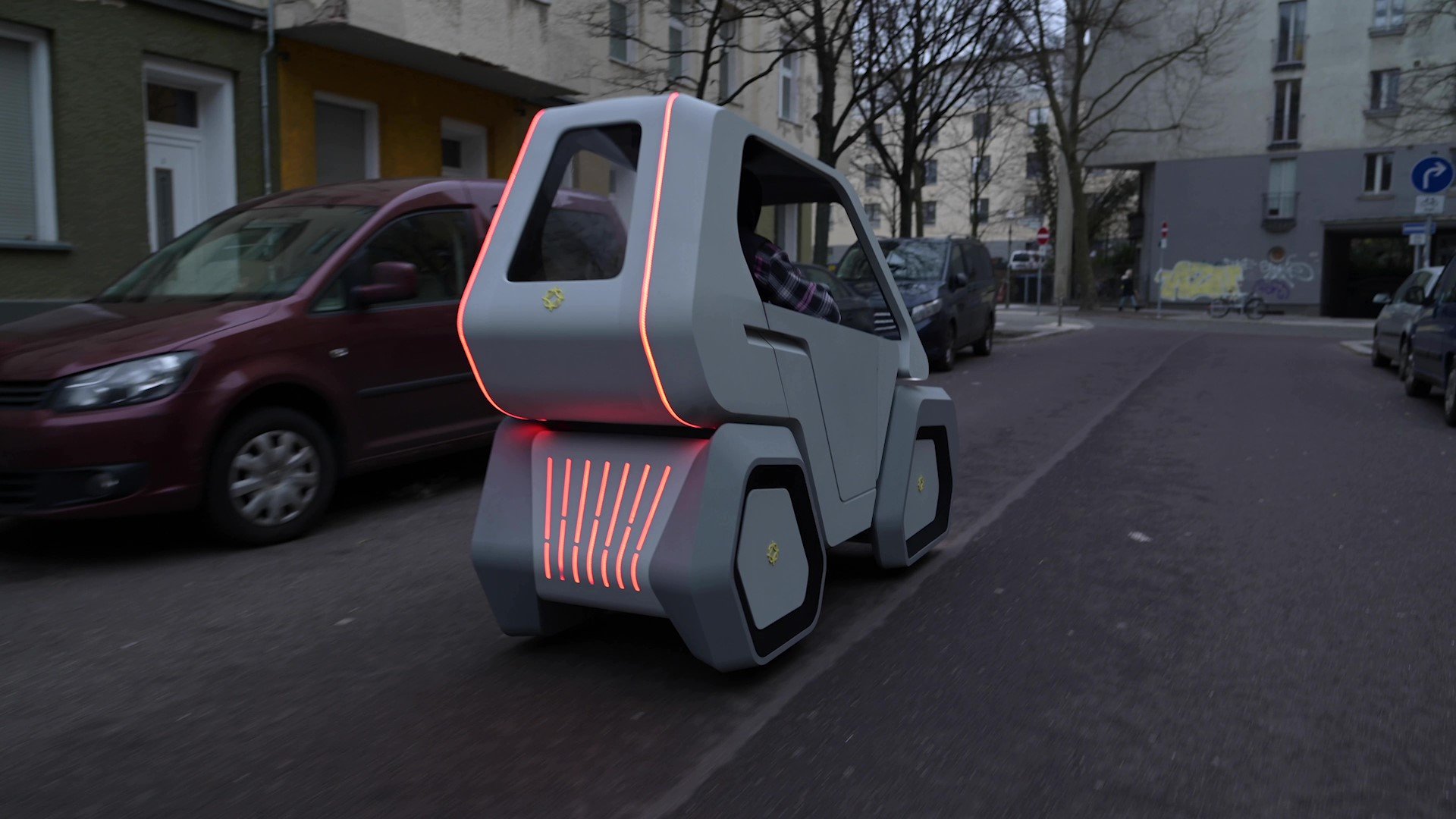

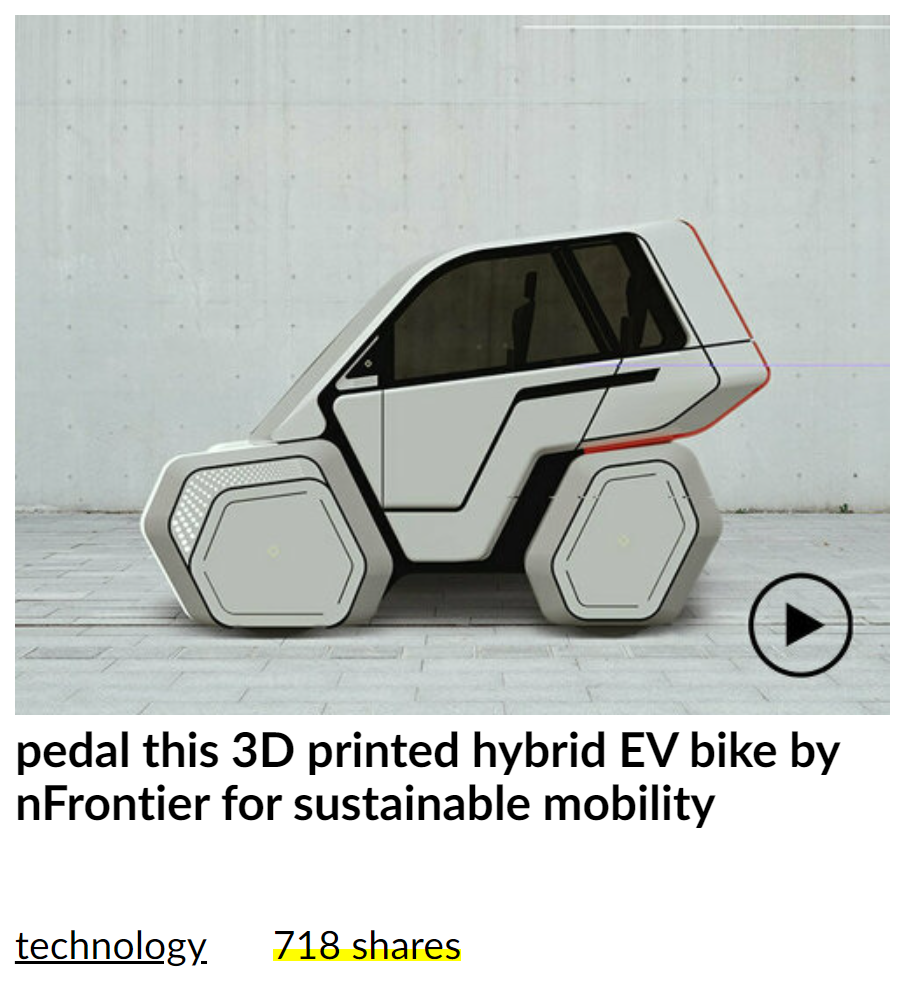

A hybrid between an electric cargo bike and a small EV, it establishes a new category of mobility to address pressing needs like climate change and the energy crisis.

It is the state-of-the-art personal urban and commuting device for environmentally conscious and forward-thinking users. Due to its dimensions and pedal drivetrain, it is technically a bike, so no driver’s license is needed, allowing users to drive in the bike lane.

“UILA merges an eBike with an electric vehicle for sustainable mobility. With a pedal-operated drivetrain like a bike, no driver’s license is needed, allowing use of bike lanes. Created with our 3D printing partner Stratasys, UILA defines future mobility by saving energy, resources, and time.”

Daniel Büning | founder of nFrontier

UI.

In collaboration with Mutabor

The visual world of UILA is vibrant, technical and thinks digital first. With an energetic yellow and a layout system that doesn't adhere to any boundaries.

UILA stands for maximum impact and minimum carbon footprint. As uncomplicated as a bicycle, as comfortable as a car, and ultimately sustainable: from the materials and supply chains to the production and use itself. We bundle all of this into one brand promise: Sustainable mobility is really fun.

The result is a lively and progressive brand that makes the innovative concept visible and tangible. UILA is Samoan and means “energy”— and the design is just as energetic.

Making Of.

UILA is a four-wheeled two-seater designed by nFrontier lead designer Joschua Kranke, using Stratasys' FDM technology for the large body components and SAF and P3 systems for higher volume additive manufacturing. It has a cargo payload of up to 250 kg, a top speed of 25 km/hr, and a range of 60-70 km. It measures 230 cm long, 170 cm high, and 90 cm wide, and may weigh up to 70 kilograms.

3D printing was essential to UILA's success. Using several additive manufacturing technologies, nFrontier cut production costs and time by producing parts in-house. Furthermore, the use of 3D printing reduced material waste and enabled local manufacture, lowering supply chain problems and transportation emissions.

Team.

Concept:

Daniel Büning

Design:

Joschua Kranke

Engineering:

Joschua Kranke, Tobias Winnen, Yomi Ajani, Tobias Storz

Fabrication and Assembly:

Joschua Kranke, Tobias Winnen, Dennis Zabel

Partners:

Stratasys (3D printing), Heinzmann (engine), Mando (pedal unit)